build parts list...

Y *20v block

N *Custom engine mounts

N *Knock sensor drilled/tapped into rear position to clear SC

Y *8.9:1 ae101 4agze pistons,

N *Flycut 5th valve pocket to make non interference engine between 20v head and gze piston

N *2nd gen 4age/4agze rods with ARP bolts, upgrade to forged when decent power made

Y *7afe oil pump housing with VR crank sensor

N *Custom 18 tooth cambelt drive pulley with 12 tooth ignition trigger wheel (4a/7a hybrid)

Y *7afe alloy sump with rear rib sectioned to clear steering rack

N *Custom cast gearbox bellhousing 4A-W, fwd bolt pattern suit mickey mouse backing plate + 7afe sump/or 20v brace

N *Winged/baffled 7afe steel pan, possibly w/ external wet pump low on exhaust side

N *Or- option2 - dry sump oil system

N *Thermostatic bypass oil filter adapter, oil cooler, mount remote filter if restricted for space

Y *20v blacktop head and quad 45mm throttles

Y *540cc side feed injectors, ex 3sgte ST205 GT-4

N *2nd fuel feed, rail/injector setup into top of plenum spraying down trumpets.

Y *Cam angle sensor - to be mounted off exhaust cam with single tooth trigger pin

Y *Coil on plug (shortened) 1mz-fe 2-wire coils

Y *3 layer 0.8mm TRD metal head gasket (or 7afe 0.3mm gasket to raise compression), oem 20v gaskets fitted elsewhere

N *ARP head stud kit

N *Exhaust ports enlarged, all ports deburred, valves deshrouded

N *Performance valve springs

N *Custom inlet plenum on silicon joiners

N *Custom water manifold off back of head (for firewall clearance)

N *Custom water outlet at front of head

Y *AE92 remote thermostat mounted under intake plenum behind S/C

N *Custom stainless water pump inlet pipe from thermostat

N *Turbo - sized between a Garrett GT3076 to a GT3582 (ford falcon typhoon GT3040)

N *External wastegate 44mm?

N *Steam pipe turbo exhaust manifold (6boost or )

N *3-3.5" exhaust system

N *Front mount air/air intercooler w/ 2.5" piping

N *Top mount water/air intercooler after SC?

Y *SC14 roots supercharger (2tz-fze Estima w/ 110mm 7rib pulley)

N *Custom SC mounts and tensioner, custom SC inlet manifold

N *Custom crank and accessory pulleys to suit toothed accessory belt

Y *55mm butterfly bypass valve sourced from 3c-te estima (diaphragm operated to suit throttle after SC system)

Y *2tz-fze S/C recirculation valve - stepper motor type for idle/cruise and/or S/C boost bleed

N *Alternator mid/low mounted exhaust side with custom mounts/tensioner to suit

Y *AE92 reduction starter - from smallport 4age (exhaust side).

N *ECU - considering a Link G4+. laptop tuned with lots of features. sequential ignition/injection etc

Y *wide band oxy for tuning purposes

N *CDI ignition?

N *water/methanol injection system?

Y/N *jza80 W58 gearbox w/ hilux front shifter position tail housing. Aftermarket gearset if won't hold together.

N *9" custom chromoly flywheel and h/d clutch (if it holds) otherwise bazda's tilton twinplate + custom fly

N *more saving moneys + sell kidney

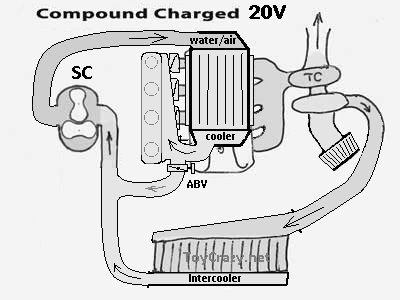

How the system works:- (Compound charged).

At idle, the SC is disengaged via a relay to the electromagnetic clutch. Intake vacuum post throttle opens the ABV (Air Bypass Valve). Any inlet vacuum above approx 8" mercury will engage the SC. If SC is engaged and throttle is closed, the air bypass valve (ABV) will be open to recirculate air from the pressure side back to the inlet side via an intercooler (to aid cooling the SC when recirculating). The ABV closes as the throttle opens in a smooth manner which brings on boost progressively. Once the ABV is closed, the engine should see the full 0.5bar (8psi) from the SC. At any stage from here the turbo will start generating boost and feed it into the SC via the air/air intercooler, the SC further compounds the incoming pressurised air forcing it into the engine via the water/air intercooler. When the throttle is released, the BOV will expel total system pressure until the pressure before the SC is depleted. This works in conjunction with the ABV which will then keep air in recirculation dependant on throttle position (inlet vacuum). The SC clutch relay has a delay timer before switching off so SC stays running between gear changes and momentary decelleration.

Note: I'd like to try out both compound and sequential systems for comparison. The following setup should allow me to test both. In theory, the compound system will ultimately make more power (with a better SC), due to having two chargers running in their best efficiency ranges whilst also promoting cylinder scavenging with it's related knock reduction benefits via near equalised pressures in intake and exhaust manifolds. I believe the sc14 will better suit a sequential system. I'd also like to try out a 'semi-sequential' system where the SC spins faster and produces more initial pressure to spool the turbo quicker, but once pressures are compounding, the ABV bypasses a controlled amount of air (not all of it) to reduce the S/C pressure ratio for optimal efficiency on boost.

Pro's

* low end torque

* top end power

*instant boost

*more power than either charger can produce alone (compound boost)

*turn s/c off for fuel economy cruise

*its unique

Con's

*complexity

*cost

*extra weight

*cramped engine bay

*heat

*increased failure rate

*build/tune time